Isotécnicamex: un éxito sin precedentes

En México se abre un nuevo camino técnico en seminarios internacionales

Durante una de las conferencias de isotecnicamex en el Centro Banamex en la Ciudad de México.

El 27 de Marzo de 2006, se llevó a cabo en la ciudad de México, en el moderno Centro Banamex, la primera conferencia Internacional, en ese país de isotécnica; isotécnicamex.

Pese de haber sido organizado a distancia, y con un corto plazo de preparación, la importante y calificada concurrencia, demostró que cuando se hacen las cosas bien, las iniciativas profesionales son acompañadas.

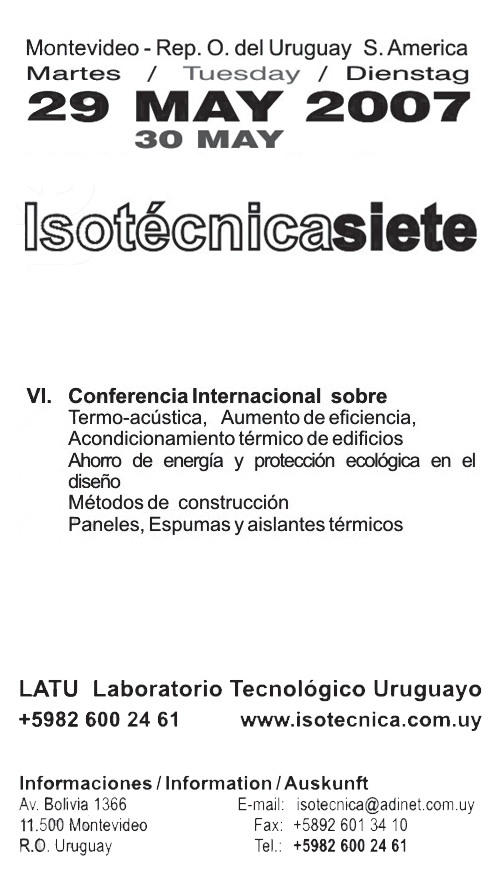

Termo-acústica, Aumento de eficiencia, Acondicionamiento térmico de edificios, Ahorro de energía y protección ecológica en el diseño, Métodos de construcción, Paneles, Espumas y aislantes térmicos y Reciclaje de plásticos especiales.

Breves reportes:

“Reciclado de Plásticos: utopía o realidad?”

Gabriel Catino

Director de Editorial Costa Nogal S.A. - Editor de la Revista Internacional Ingeniería Plástica - Experto Internacional en tecnología de Plásticos, autor de libros del sector. - Docente en la Universidad Católica (Uruguay) sobre la temática

El tema de reciclaje de plásticos está pasando por un momento de relevancia, en lo que respecta a interés general, particularmente referido a Latinoamérica. Temas ya asumidos por las sociedades en los países de primer mundo, recién ahora están tomando una mayor preocupación en la región. Parte de este creciente interés por los materiales post consumo, se debe más que a una preocupación ambiental, a un asunto de interés económico: el material post consumo tiene un gran valor económico.

¿Que hace darle valor al material desechado? En primer lugar el aumento desenfrenado en los costos de las materias primas plásticas, hace del material post consumo, en la medida que se recicle, una materia prima accesible a menor costo.

Por otra parte la constante sustitución de materiales tradicionales por plásticos, junto al ingreso de compradores a gran escala, como China, y sumado a los imponderables técnicos o de otras causas que han detenido producciones petroquímicas, caso los daños ocasionados por el huracán Katrina, han provocado situaciones de desabastecimiento en la entrega de materias primas a nivel global, con el consecuente aumento de precio por una mayor y desesperada demanda.

Esto trae la consecuente prioridad de atención a los clientes más importantes, por parte de los productores petroquímicos, lo que deja para las regiones más pobres e inestables una disminución de la atención comercial, menor disponibilidad de materiales, o mayor plazo en el tiempo de entrega. Todo esto llevó a aumentos de precios que son difíciles de trasladar al consumidor final. Cuando los mercados son abiertos (no todos los países juegan con las mismas reglas comerciales), hay que buscar soluciones alternativas. Y el reciclado de materiales post consumo, es una alternativa. Entonces lo primero que debemos entender es que allí tenemos un material que puede y debe ser transformado en algo diferente y de valor. Hoy se recicla todo material plástico, y existen todos los sistemas posibles para, o bien reingresarlos al mercado en otros productos de similares características, reciclaje físico, o bien transformados en componentes químicos, reciclaje químico, o bien obtener de ellos energía, incineración. En todos los casos, hablamos de valor de recuperación. Tenemos que tener en cuenta que reciclando materiales post consumo, es menos utilización de materias primas no renovables y ayudamos al medio ambiente.

Que mejor para entender lo que significa reciclar, que las propias palabras del padre de la Química, Antoine Laurent Lavoisier, 1743-1794, cuando nos lega: “En la naturaleza nada se crea, nada se destruye, todo se transforma”.

“Calidad de Vida: cómo lograr Confort Térmico en las diferentes Zonas Geográficas de México.”

Jenny Tardan Waltz

Arquitecta, Universidad Anáhuac - México. - Directora General de la Asociación de Empresas para el Ahorro de la Energía en la Edificación, A.C.

Jenny Tardan, Directora General de AEAEE, la Asociación de Empresas para el ahorro de la energía en la edificación, nos dio un panorama general sobre la calidad de vida que se puede tener en la vivienda o en la edificación, por medio del confort térmico, de acuerdo a las zonas climáticas de México. La AEAEE es la Asociación de Empresas para el Ahorro de la Energía en la Edificación, A.C., creada en México en el año del 2003, por empresas privadas y organismos públicos mexicanos, todos líderes en el sector de la eficiencia energética aplicada a las envolventes térmicas de las edificaciones no-residenciales y vivienda.

De izquierda a Derecha Chong Hak Tay, Rafael Camargo, Gabriel Catino, Jenny Tardan, Jörg Thompsen y Jorge Sandoval

Short report in English:

“Plastic foam: pro´s and con´s strength and weakness”

“Sandwich Panels under the magnifying glass.”

Jörg P. A. Thomsen,

Consultor Internacional en los temas de: fabricación, aplicación y comercialización de espumas sintéticas y afines - Director ISOTECNICA - Vicepresidente Comisión Ambiental CIU (Cámara de Industrias) / Asesor temática ambiental AUIP. Articulista en revistas técnicas internacionales / Integrante Comité UNIT_ Comportamiento térmico de edificios / Miembro DGS-ISES Int. Solar Energy Society. Industrias del Uruguay)

From isotecnica / URUGUAY held two speeches: the first one focused on thermal insulation foams strengths and weaknesses and the other on stressed skin panel application. As always Thomsen shared his long and vast experience with the audience and gave us an overview about the key issues where to look on, while choosing a foam for insulation or how to determine the best joining solution between panels and/or with the masonry for instance.

With his well known pedagogical style, he told us where to put an eye on. Instead of focusing on the chemistry of the structure of the foam and falling into the influence of fashions and/or temptations driven by hollow advertisings, Thomsen told us to focus on the real issues: fire behaviour of the complete wall or roof design (specially the joints) and the vapour barriers and the accurate sequence of layers in order to avoid internal vapour condensation. Capillarity, thermal bow, electrochemical problems, de-lamination, long term behaviour, joint design, etc. etc. were also part of his vast repertoir.

“FRP - Fiberglass Reinforced Plastic for a clean, cold future.”

Jorge Sandoval

Gerente Regional Crane Composites Kemlite Inc. BBA - Economics University of Texas, San Antonio Texas, USA. / Asesor de la industria de la fabricación de equipo de transporte refrigerado, construcción y laminados de paneles a base PRFV (FRP)

Kemlite’s Glasbord® frp with Surfaseal® finish is a moisture and impact resistant sanitary wall and ceiling panel. Surfaseal, a sealed protective surface, is resistant to scratches, abrasions, staining, and damage due to harsh chemicals. Glasbord is available in different colors and finishes, and can be cut and drilled for easy installation. Accessories such as color-coordinated moldings and rivets are also available to complete the installation. Glasbord is used in a wide variety of applications where ease of cleaning, sanitation or abuse resistance is required including food processing plants, cold rooms, industrial kitchens, hospitals, restaurants, bathrooms, etc. It is one of the options isotecnica recommends as skin of sandwich panels, to be produced on the continuous or discontinuous sandwich panel laminating machinery.

“Long life sealants based on Modified silanes”

Lars Andreas Müller

Business Manager South America. General Industry Teroson Henkel. / Since 1990 dedicated to the Automotive, Construction, Assemblyu and surfaceTreatment Markets. / Sealants and Metal pretreatment Chemicals

in representation of TEROSON Henkel, gave a conference in a pedagogically very proper way and of a big value for the listeners.. That is why he got such a high qualification from the audience.

In accordance to his report, the insulation industry has faced severe challenges during the last decade.. All agents of this industry have been under strong pressure to increase the performance and cost / benefit relation of their products and services. Not aside of this Henkel has developed it’s ultimate technology for the

assembly of sandwich panels adhesives complying with EN-13501 regulation. With this unique technology, Henkel is supporting a long lasting investment culture once this special type of panels are intended to reduce operational

costs such as insurance and maintenance of cold storages. The technology of MS- Sealants (Modified Silanes), has also complemented the portfolio offering sealants with substantial benefits to the end-user during the assembly of cold storages or insulated areas due to remarkably superior ageing performance of these type of sealants compared to regularly used PU-Sealants.

“Bonding Skins: The Role of Adhesives in the Manufacture of Insulation Panels”

Rafael E. Camargo, Ph.D.

Eng. Dipl in Chemical Engineering (Universidad Pontìficia Bolivariana in Medellin) / Ph.D. In Chemical Engineering and Materials Science (University of Minnesota), Americas Elastomers / Platform Manager for the Global Development Team of Huntsman Polyurethanes, Auburn Hills, Michigan

Sandwich type insulation panels are being widely used in modern construction. These panels provide both insulation and structural elements. Because of the increasing performance demands in these products, panel integrity and reliability are important. Polyurethane adhesives provide an important element in maintaining the integrity of these panels. Huntsman Polyurethanes has long been a leader in the formulation of of adhesive systems based on methylene diphenyl di-isocyanate (MDI). It has long supplied the panel industry with one and two component adhesive systems. In this presentation, new adhesive systems for continuous panel laminating (CPL), based on its Suprasec® 2026 MDI based polyisocyanate have been described. These new adhesive systems display increased performance, as measured by a higher bond strength, and can be adjusted to achieve faster green strength and final flexibility under different production line conditions. These products allow panel manufacturers to maximize line productivity and can be used with a variety of substrates such as expanded polystyrene (EPS) or mineral wool. To illustrate the improvements in these new adhesives, Figure 1 below shows the bonding strength as a function of mixing ratio for this new generation of adhesives compared to early systems already used widely in the industry. The systems are formulated for an optimum isocyanate to polyol mixing ratio by volume of 1.5 to 1.0 (or 1.7 to 1.0 ratio by weight). Huntsman Polyurethanes pioneered the development of MDI technology over 40 years ago. Today the company maintains an unparalleled understanding of the chemistry it invented through continual innovation and work with customers to support formulating, processing and handling requirements.

“Fire, Foam & Panels.“

Chong Hak Tay

MBBS University of Singapore - Master of Fire Safety Engineering University of Western Sydney / Director Genaplastr, Singapore / Affiliated companies in Malaysia MBBS University of Singapore - Master of Fire Safety Engineering University of Western Sydney / Director Genaplast, Singapore and Affiliated companies in Malaysia

Of Genaplast Private Limited Singapore gave an overview of enclosure fire and fire tests; reviewed the ‘tsunamic’ impact of the insurance driven changes on the insulated panel industry in the UK that was spreading to other countries; the 2004 research by Branz NZ on Improving The Fire Performance Of Polystyrene Insulated Panel In New Zealand, which found that fire did not propagate in polystyrene foam insulated panels (PIP) as was commonly assumed and the current panel suspension designs were adequate. The report also found steel components superior to aluminium in corner angle joints and the closer placement of steel rivets in interlocking panel joints reduced the heat release rate of the panel and delayed its commencement. He also showed how XFR-EPS a developmental product, which by encapsulating EPS beads, obtained superior fire retardation, and demonstrated this improved performance against commercial fire retarded EPS, PUR and PIR when tested under

Volver

|